We use corrugated boxes on a regular basis to store our products or transfer them to places. Industries and factories also use them for storage and similar purposes as they are cost-effective and eco-friendly. Have you ever wondered what happens to these boxes when the work is over and they are thrown in the landfills? Many boxes end up in the trash dumps, but some get a second life as they are picked for recycling. This article will discuss the exciting journey of recycled corrugated boxes and how they positively impact the environment.

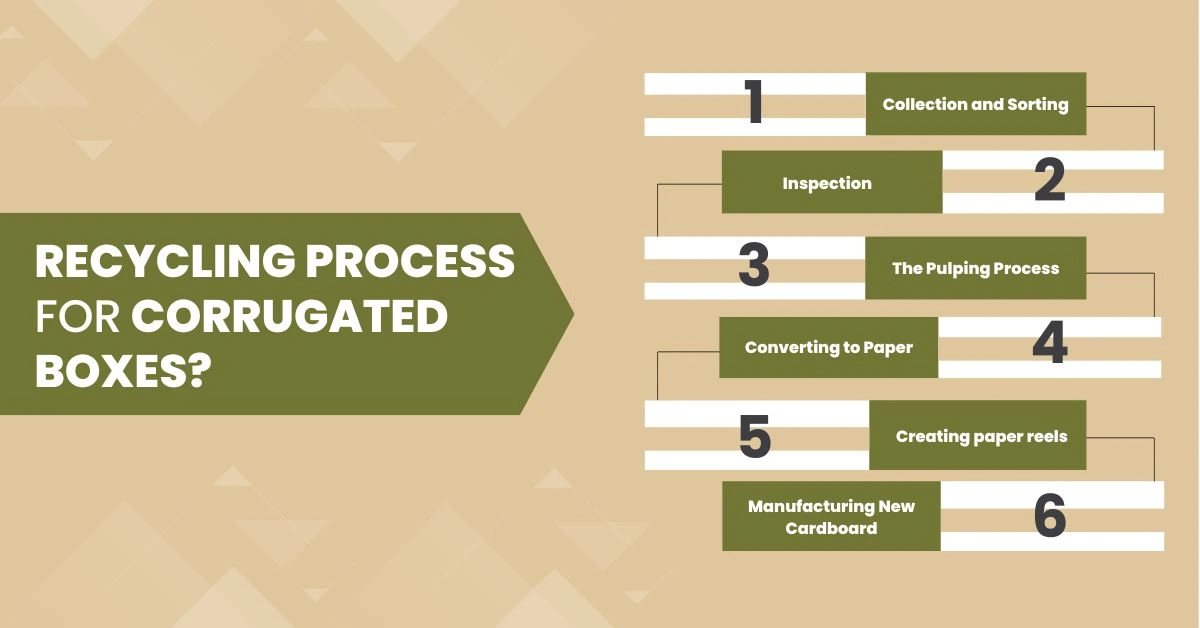

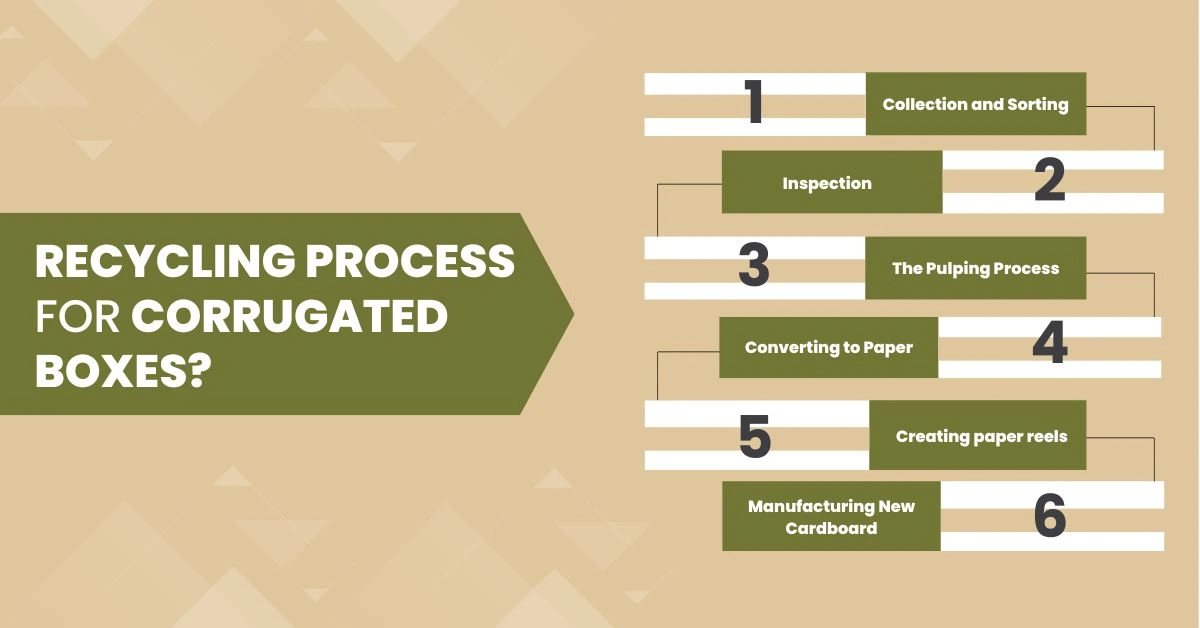

There are many steps that are involved in the recycling of corrugated boxes, and all of them are eco-friendly, which does not affect the environment. Having a look at the below-mentioned step will provide you with brief information regarding the process.

The initial step in recycling corrugated boxes is to collect them from various locations. A huge amount of these boxes are found near the factories and are in the form of industrial waste. Next, these boxes must be sorted accordingly to maintain quality when new products are manufactured.

Upon reaching the recycling centers, the cardboards are inspected individually to check whether they contain plastic or other substances. The main motive of this process is that only good-quality cardboard pieces reach the paper mill.

Once the cardboard reaches the mills, it is soaked in water before getting pulped. This step creates a soupy mixture as it breaks down the cardboard into fibrous building blocks. The soupy mixture formed is further cleaned to remove the remaining contaminants.

After all the residues are removed, the good-quality pulp moves to the next stage, where it gets spread out and pressed, and later dried up to form fresh sheets. These sheets are later rolled into large reels and then transferred for the next step.

Here, the giant reels are cut according to their required sizes based on their requirements. This process is crucial as it shapes the reels for various products that are required in the market.

This is the ultimate step where the fresh papers enter the corrugation process and new cardboards are manufactured. These cardboards are later cut into required sizes and folded into boxes, which can be used to store or deliver products to various locations.

Corrugated boxes positively impact the environment and boost our eco-friendly practices. The recyclable nature of these boxes directly benefits the preservation of trees. Moreover, they are easily disposable, and the process does not emit much carbon. Now, at times, you might encounter corrugated boxes in the form of industrial waste littering the ground or in landfills. In such situations, too, the land is not damaged to a great extent compared to plastic products, as corrugated boxes decompose at a faster rate. Thus, by opting for these boxes, we can contribute our support towards sustainability and environmental protection.

For in-depth comparison, read our blog, Environmental Impact: Cardboard vs. Corrugated Boxes.

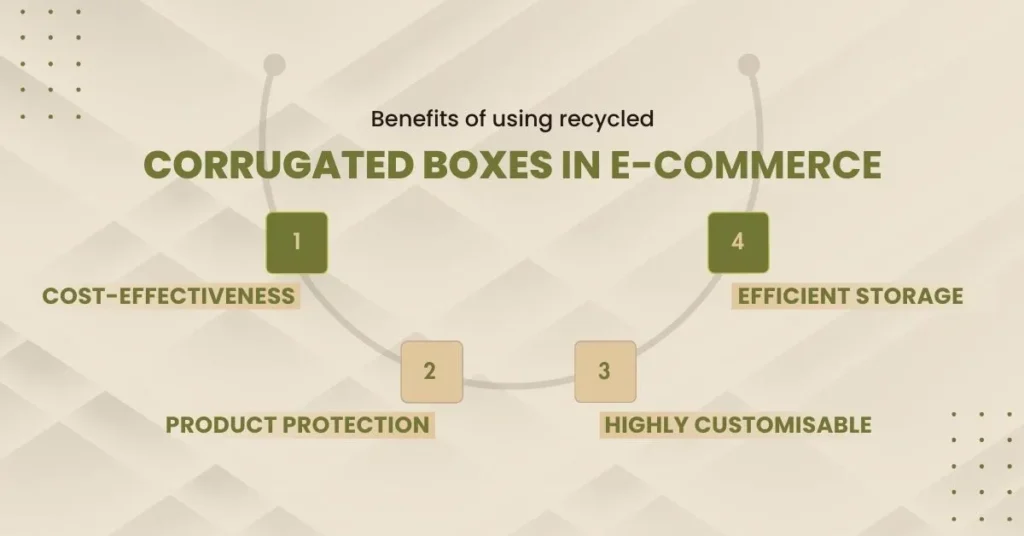

Opting for recycled corrugated boxes in e-commerce companies can positively impact the lives of consumers by not harming the environment. Below are some points that will assist you in exploring its benefits in a brief manner.

The overall recycling process of corrugated boxes is cost-effective, and brands will have to spend comparatively less to acquire these boxes. The shipping cost is also reduced as these boxes are lightweight and can be transferred without much hassle. This will save a good amount of revenue, which can be used for other purposes.

The three-layer cushioning of these boxes provides enough protection to the delicate products while they are shipped to a distant location. The layered design has the ability to sustain vibrations and instability even when these boxes are roughly managed.

Branding is an important aspect of any e-commerce business, which assists in driving more sales. The plain surface can be used for labeling, which is sure to attract the majority of the audience. The build of these boxes is rigid, and no excessive tapping is required, which makes it easy to open for all individuals.

The uniform surfaces of corrugated boxes mean one box can be placed on top of another. This allows the accumulation of more boxes in the maximum storage space, thus saving a good amount of money.

The debate between recycled and new corrugated boxes is quite on the rise, as each of these boxes has some unique sets of benefits. Although both might look similar and serve the purpose of packaging and protecting the environment, their impact is different. The recycled corrugated boxes are prepared from industrial wastes and leftovers, which are thrown in landfills. The overall process reduces the need for fresh wood pulp and also plays a crucial role in maintaining methane emissions, which are associated with the decomposing of papers.

On the other hand, new corrugated products are prepared from fresh wood pulp derived from trees. The major concern with this process is that the manufacturers source wood from the forest for its preparation, which contributes to deforestation. So if you pick one among recycled corrugated boxes vs. new ones, then it’s always a good choice to pick the recycled one.

Check our variety of corrugated boxes, like 3 ply boxes, 5 ply boxes, 3 ply multi-depth boxes, bottom lock boxes, tuck-in boxes, and more.

Conclusion

Thus, in this article, we have learned about the recycling process of corrugated boxes and how a small step can have a positive impact. So, each time we put a used corrugated box in a recycle bin, we are also a part of this amazing process that changes the environment. Moreover, it saves the trees from getting cut and assists in making the planet clean.

Tags :

Share the article:

Recent Posts

Today packaging isn’t just about the containment and protection of the product

We use corrugated boxes on a regular basis to store our products

The selection of the right packaging materials is crucial to ensuring the

Corrugated cartons are lightweight structures that are commonly used to pack various

Corrugated boxes are containers that we commonly use to store and ship

Packaging is one of the most important parts of any business, and

Whenever we purchase any items or products either online or offline, they

In the world of shipping and packaging, two players that stand out

Contact Us

Customer Support

Company Information

Copyright © 2025 Pacfo International Private Limited